We are Manufacturer, Supplier, Exporter of RO Plants (Reverse Osmosis Plants) and our setup is situated in Pune, Maharashtra, India. We also provide Installation, Annual Maintenance Contract (AMC) Services, Operation And Maintenance Contract Services, Chemicals, Equipments, Spares (Spare Parts) for our whole product range.

Reverse Osmosis (RO) is a technology that is used to remove a large majority of

contaminants from water by pushing the water under pressure through a semi-permeable

membrane.

Reverse Osmosis is the process of Osmosis in reverse. Whereas Osmosis occurs naturally

without energy required, to reverse the process of osmosis you need to apply energy to

the more saline solution. A reverse osmosis membrane is a semi-permeable membrane that

allows the passage of water molecules but not the majority of dissolved salts, organics,

bacteria and pyrogens. However, you need to 'push' the water through the reverse osmosis

membrane by applying pressure that is greater than the naturally occurring osmotic

pressure in order to desalinate (demineralize or deionize) water in the process,

allowing pure water through while holding back a majority of contaminants.

How does Reverse Osmosis (RO) work?

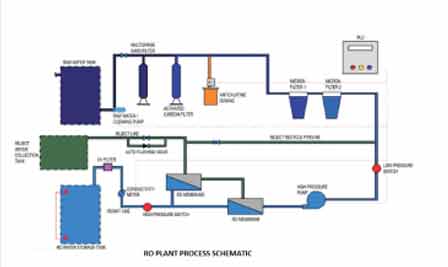

Reverse Osmosis works by using a high pressure pump to increase the pressure on the salt side of the RO and force the water across the semi-permeable RO membrane, leaving almost all (around 95% to 99%) of dissolved salts behind in the reject stream. The amount of pressure required depends on the salt concentration of the feed water. The more concentrated the feed water, the more pressure is required to overcome the osmotic pressure.

The desalinated water that is dematerialized or deionizer, is called permeate (or product) water. The water stream that carries the concentrated contaminants that did not pass through the RO membrane is called the reject (or concentrate) stream. As the feed water enters the RO membrane under pressure (enough pressure to overcome osmotic pressure) the water molecules pass through the semi-permeable membrane and the salts and other contaminants are not allowed to pass and are discharged through the reject stream (also known as the concentrate or brine stream), which goes to drain or can be fed back into the feed water supply in some circumstances to be recycled through the RO system to save water. The water that makes it through the RO membrane is called permeate or product water and usually has around 95% to 99% of the dissolved salts removed from it.

Our Reverse Osmosis Plant has the following Advantages:

- Actively rejects ions and contaminants.

- Reduce Water that meets the most demanding specifications.

- Allow the membrane to continually clean itself

- Higher pressure from the pump to push the fluid through the membrane.

- Capable of rejecting bacteria, salts, sugars, proteins, particles, dyes and other constituents.

- Works in various molecular weights.

- Drinking Water purification

- Water and Wastewater purification

- Food industry

- Metal Production industry

- Automobiles Industry

- Agriculture Industry etc.

- Pharmaceutical Industry etc.

We Offer we offer extremely reliable and simplified range of Customized

semi-Auto or Automatic RO Plants. Being user-friendly and aesthetically excellent, these RO

Plants have become one of the coveted choices available in the market.

These are designed in capacities ranging between 50 lph and 10000 lph and ever more to

suffice to the discerning needs. The well designed pretreatment and PLC / Controller based

automation are done as per specific requirements.

.jpg)